Direct Thermal vs. Thermal Transfer Labels – Difference

Thermal printers are essential in the smooth running of a business, big or small. Your thermal printer utilizes two main thermal printing methods when printing: direct thermal vs. thermal transfer labels.

Choosing between these two can be confusing, but this article has a solution to that problem. It explains the difference between direct thermal vs. thermal transfer labels. Need any help when purchasing thermal ribbons or thermal paper rolls? Our team of experts at Graphic Tickets System is here to help.

Difference Between Thermal Transfer vs. Direct Thermal

Direct thermal labels have a coating sensitive to heat. This coating makes them turn black when heated directly by the printer, resulting in the formation of images and text.

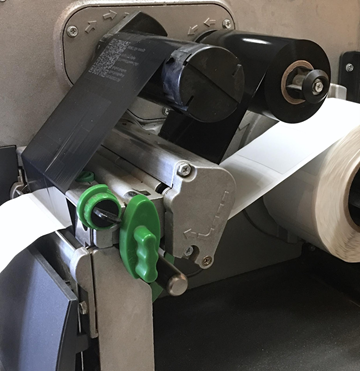

The thermal transfer label has a ribbon that contains heat-sensitive ink. When in contact with the thermal printer, the ribbon transfers the ink to the surface of the printing media, forming images and text.

What are Direct Thermal vs. Thermal Transfer Labels?

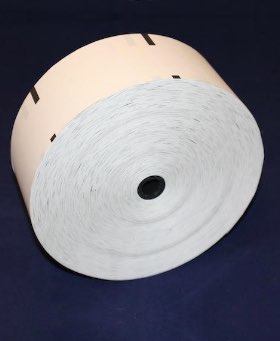

Direct thermal paper is a low-cost label that uses a thermosensitive material to produce thermal barcode labels for product pricing. During thermal transfer label printing, a thin ribbon film wound inside the printer imprints the pricing information onto the label material. A black coat made of resin or wax covers this ribbon.

How do Direct Thermal Labels and Thermal Transfer Labels Work

Before you can tackle that effectively, you have to examine how thermal printers work. Thermal printers produce images on paper by producing heat, causing a chemical reaction on the paper, and releasing the reactant and dye that form the images and text. While both direct thermal and thermal transfer utilizes this basic principle, they don’t work in the same manner when creating the final printout on the printing paper.

As the name suggests, a direct thermal label printer uses heat-sensitive labels, and they form prints when the thermal paper passes through a thermal print head, with the dye and reactant on the printing paper. The heat then turns the paper’s coating black, resulting in an image on the printing media, hence direct thermal printing. Thermal transfer printing works by using a printhead with small pins, which become hot, melt the wax on the ribbon that contains the dye, and the dye forms an image on the printing paper.

Common Applications of Direct thermal vs. Thermal transfer labels

Applications of Direct thermal labels

- Shipping labels: Many companies use shipping labels made from direct thermal labels. They are cheaper and only necessary during transit.

- Food labeling: There is no use of ink in direct thermal labels. They thus cannot contaminate the food when you use them as food labels.

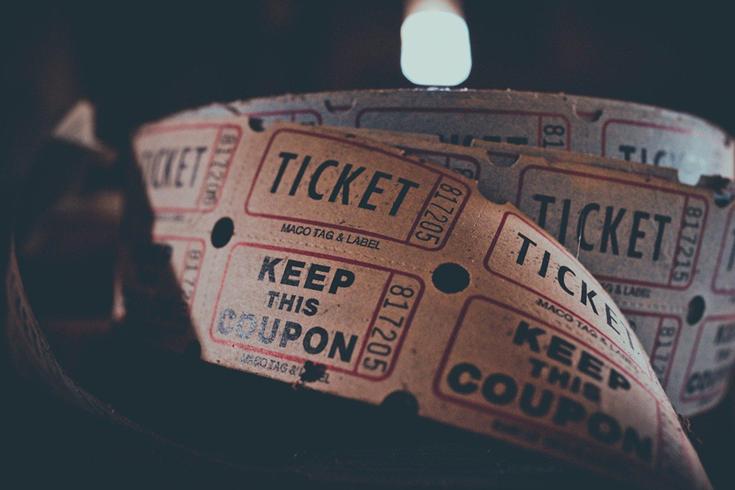

- Event tickets: Direct thermal printers have a higher printing speed than traditional ones. It thus makes them suitable for creating a large number of tickets in the shortest time possible.

- Name tags: are best for making name tags because they are cheap and last for a short while.

Applications of Thermal transfer labels

- Assets tracking: is an excellent way of keeping track of your items. You can label your purchases using thermal transfer labels because they are durable.

- Laboratory specimens: Thermal transfer labels can endure freezing temperatures and different laboratory procedures. It thus makes thermal transfer labels suitable for use in the laboratory.

- Product IDs: Such as identification labels are made using thermal transfer labels.

- Library labels: Thermal transfer labels are accurate and have good clarity. As a result, it makes them the best for creating library card prints.

Advantages of Direct Thermal labels and Thermal Transfer Labels?

Benefits of Direct Thermal Labels

- Saves time: With no ribbons replacement required, exchanging the printer is easy and quick, saving time during a printing session.

- Cost Saving: These heat-sensitive labels do not use either ribbons or ink. As a result, you won’t spend a lot of money running them.

- High volume prints: Their high speed makes them produce many images within a short time.

- Reliability: You can always trust direct thermal labels to give you high-quality prints.

Advantages of Thermal Transfer Labels

- Colored prints: these labels can produce images of various colors. You can thus use them in color-coding.

- High Accuracy: thermal transfer labels can make images with right-edged definitions and the required width.

- Durability: can last for more than six months without fading. This longevity is because of the extra customizations added during the transfer labeling process.

- Resistant: using the thermal ribbon as a transferring agent makes thermal transfer labels produce weather and chemical-resistant graphics.

Disadvantages of Direct Thermal vs. Thermal Transfer Labels

Disadvantages of Direct Thermal Labels

- Direct thermal labels are Monochrome: They cannot print colored images like those used for color-coding.

- Fading: These heat-sensitive labels fade when exposed to continuous sunlight or heat.

- Little scratch resistance: Thermal direct labels wear off when you scar them.

Disadvantages of Thermal Transfer Labels

- Wrinkles: The ribbons might wrinkle during the winding and unwinding process. This wrinkling lowers the quality of the thermal labels.

- Costly: They are generally more expensive than direct thermal paper. The high prices are due to the regular replacement of the ribbons used in printing.

- Time-consuming: Changing and replacing the thermal ribbon takes time. It thus makes thermal transfer labels unreliable when used in large industries.

- Limited color printing: Each thermal transfer printer is compatible with only one type of color label. If you have green thermal labels, you will need a compatible printer for that label.

How to Choose the Right Thermal Label?

When selecting the correct thermal label, consider the cost of the brands. You should also ask yourself how long you want the labels to last. Thermal transfer labels are long-lasting but are more expensive. Direct thermal labels are cheaper but have a shorter shelf life. They also print in one color.

Still confused about which thermal label to choose? Contact our team now, and we will be happy to help you out. you encounter any issues with your thermal printer, such as unclear printing, we have a helpful article on what to do when the thermal printer is not printing clearly. Check it out!

Conclusion

Heat transfer labeling is essential for the smooth running of your business. And going for the right one will help you avoid incurring any losses when using them. Knowing the difference between thermal transfer vs. direct thermal will help you choose the right one.

Visit Graphic Tickets and Systems today to get the best thermal paper rolls in the market.