Direct Thermal Label and Its 5 Benefits

Advancing technology in the printing industry has led to the introduction of thermal printing. Unlike traditional printing methods, thermal printing is increasingly becoming popular for its accurate, high-quality, and clear definition text. Thermal printing assures quick printing with unmatched efficiency.

However, you should choose between two main thermal printing technologies, thermal transfer and direct thermal labels, for your printing needs. Knowing the difference between these two technologies is prudent for any business with significant printing needs. Remember to order thermal papers for your thermal label printer from Graphic Tickets.

Common Applications for Direct Thermal Label

Initially, direct thermal labels were used for specific products, particularly meat, dairy, and poultry. However, technological advances have enabled the use of thermal papers in different products in the market. Currently, direct thermal paper is used in printing the following;

- Barcodes for various products

- Thermal shipping labels

- Name tags for patient and visitor identifications

- Tickets and receipt printing

- Coupons

- GHS compliant labels

How Do Direct Thermal Labels Work?

Direct thermal labels are best for high-quality barcode printing needs, such as shipping and mailing labels, nametag labels, eCommerce shipments, and receipt labels. The direct thermal label has a unique printing process. Unlike other printing methods that use a ribbon, a direct thermal label has a heated print head, which creates the chemical reaction responsible for creating imprints.

The reaction creates a scannable image, which is transferred to an adhesive label paper. Note that direct thermal labels printers can only print in adhesive label paper media. This printing option is simple and efficient since you only need the label paper and thermal print head to create quality printouts.

Difference Between Thermal Transfer and Direct Thermal Label

As mentioned, thermal transfer and direct labels are the two main types of thermal labels. Unfortunately, most people use these terms interchangeably without recognizing the difference between these two labels. Essentially, thermal transfer labels require a ribbon to be printed. The printer is fed with both the paper label and a ribbon when printing thermal transfer labels.

The printer heats the ribbon, which transfers ribbon wax and resin into the paper label. Thermal transfer printers use ribbons the same way inkjet printers use ink when printing on paper. However, heated resin and wax are used to replace ink. Heat transfer labeling ribbons are available in multiple colors, allowing for multicolored and custom thermal label printing.

On the other hand, direct thermal labels don’t require ribbons to print. The paper labels are fed into the printer, and the printer applies heat to the label directly. The print head heats the label during the print process, initiating a chemical reaction that darkens the heated portions. Receipt printers are the best example of direct thermal printers.

Unlike thermal transfer printers, direct thermal printers don’t use ribbons. Therefore, they are comparably smaller and can fit a small space. They are also cheaper to maintain since there are no costs of buying ribbons. However, on the downside, direct thermal labels are not scratch-resistant and won’t last long, especially if exposed to direct sunlight.

That said, below are the main types of thermal transfer and direct thermal receipt printing papers;

- Bond paper – also called woodfree paper, is a one-ply paper that requires ink and cartridge to print. The bond paper surface doesn’t shine like thermal paper and won’t change color when scratched on the surface.

- Thermal paper – it is a commonly used paper in the POS industry. It doesn’t require ink or a cartridge to print like bond paper. It has a smooth surface and is coated with dye chemicals. Thermal papers change color when exposed to heat to display text and images.

- Carbonless paper – unlike bond and thermal paper, carbonless paper has between 2 and 4 plys with different colors. However, like bond paper, it requires ink ribbons and cartridges to print. Carbonless papers have chemicals between layers that transfer text or images between the paper layers.

Top 5 Benefits of Direct Thermal Label

The benefits of direct thermal labels go beyond not having to deal with ink cartridges or the noise of regular printers. As mentioned, direct thermal label printers use heat from the print head to produce clean text and images. Key benefits of thermal label printers include;

Time-saving During the Printing Process

Direct thermal printers offer unmatched speed. Compared to traditional printers, it takes less than a second to print using thermal printers. As mentioned, these printers don’t have a ribbon. Instead, they use a print head that moves back and forth quickly, applying heat to the print label.

The speed provided by direct thermal printers comes in handy in large-scale printing needs. For instance, it takes a few minutes to print more than 100 shipping labels, a process that would take hours with traditional printers.

Elimination of Wrinkling Due to Ribbons

Direct thermal label printers are very reliable, and you won’t have to worry about the wrinkling of your thermal stickers. For starters, there is a slim chance of thermal printers breaking down when in use. Besides, there is no chance of experiencing paper jams since thermal printers have no moving parts. The significant reduction of moving parts in a thermal sticker printer means that only a few parts can break down.

Reduction in Physical Inventory

Investing in a thermal printer is also very economical. While the initial cost of buying thermal printer labels is high, you will enjoy printing with minimal inventory requirements. Thermal printers don’t use cartridges, which require a monthly stocking. Also, as mentioned above, thermal printers have minimal moving parts, which translates to low maintenance costs. All you should do is keep the thermal printer’s print head clean.

Accuracy

Direct thermal label printers are very accurate for a simple reason. Unlike traditional printers, the ink used in thermal printers comes with the paper label and not the printer. Therefore, there is no ink from the print head, which can possibly smudge the paper label.

Environmentally Friendly

Unlike thermal transfer printers, direct thermal label printers don’t use ribbons for printing, making them environmentally friendly. Printing ribbons are made from crude oil, making them an environmental concern. Direct thermal labels are BPA and phenol-free.

Conclusion

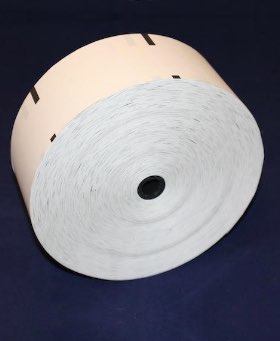

Direct thermal label printers use continuous sheets or reels, which are cost-effective for creating barcodes and labels on a large scale. Maintaining these printers also costs less compared to laser, inkjet, and thermal transfer printers. However, remember that direct thermal labels can’t last long if exposed to direct sunlight. That said, order your direct thermal printing labels for your business from Graphic Tickets.